|

I’ve been using rapid prototyping or 3D printing, as it is now referred to, since the late 80s, and it is a fantastic and valuable tool. With Stratasys’s patents expiring and everyone jumping on the bandwagon to make them, there are literally hundreds of cheap 3D printers available. Since the 3D fad has become mainstream I have been asked numerous times “where is your machine”?

I’ve always been of the view that these machines, the cheaper ones which are affordable to small business and home users, do not provide a print quality I would be happy to supply to a client, as well as being extremely slow. Additionally, speaking to 3D printing enthusiasts, it also seems that using these printers is a bit of a black art and to want to use them you really had to be an enthusiast. So quite happily I have been leaving 3D printing to the specialist bureaus and focused on what I do best, which is design. However recently at the National Manufacturing Week, I came across a couple of relatively in-expensive printers for under $10k. These provided a quality model of a bottle (a product I regularly design) that I would be happy to show clients. What excited me more was that some of these printers could produce a fairly large part quite fast. It was nearing the end of the financial year. I had the fund’s. Was now the time to buy? For the first time in 30 years I was serious about owning a printer of my own. So this was the first time that I really started doing homework about the finer details of these machines. I was getting into the nitty-gritty of speed, materials, ease of operation, remote control, maintenance et cetera. I had requested two vendors to supply me with sample prints. I was excited. I put the proposal to my partner whose first question was “Is this healthy?” Now there’s a question I had never thought to ask. We design, mould and use these materials every day. Obviously it’s healthy, what could not be? So I started to do a little homework and lo and behold printing in some materials is not healthy. There are vapours and ultrafine particles that are released in the print process and none of these machines, as far as I can find, adequately address this issue. Some have cabinets. Some have filters. However, speaking to the suppliers of these machines, none of the machine designs provide a complete solution yet. Even the HEPA filter fitted in one of the machines only filters a little over 90%. None of the many suppliers I assessed raise these issues as part of their sales pitch - quite obviously, and possibly some are not even aware of these issues. The supposed solution on the web appears to be to work in adequately ventilated areas and not to use the filaments that give off the most toxins (ABS, HIPS). Is this an adequate solution? This seems to me to be an unresolved situation and incomplete product design. So until someone can come up with an office or home 3D printer solution that provides adequate safety features, so they are not detrimental to the health of my co-workers and family, I will continue to tell people “My machine is at The Bureau”.

1 Comment

I just bought a mountain e-bike. It would be good if the tax office could realize that my new purchase should be a tax deduction. This is because now more than ever you will probably not find me in my office trying to solve tricky design challenges, but out in the bush, soaking up nature’s bounty, riding my new bike. This is I believe, integral to my design process.

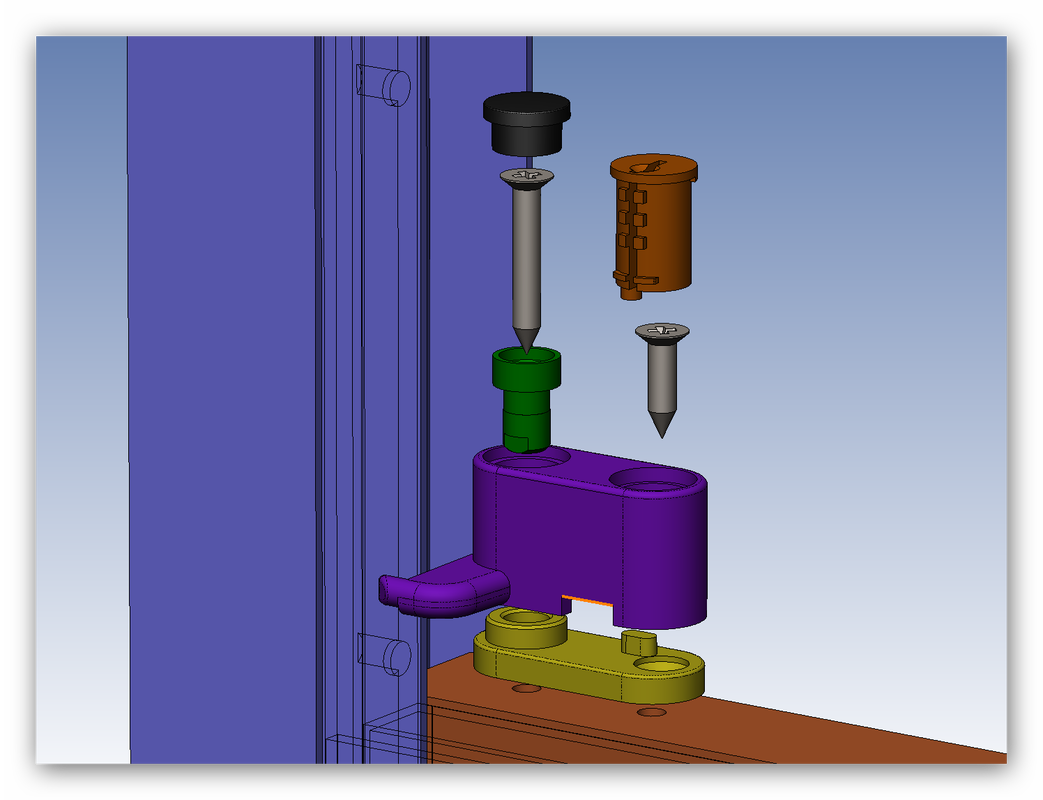

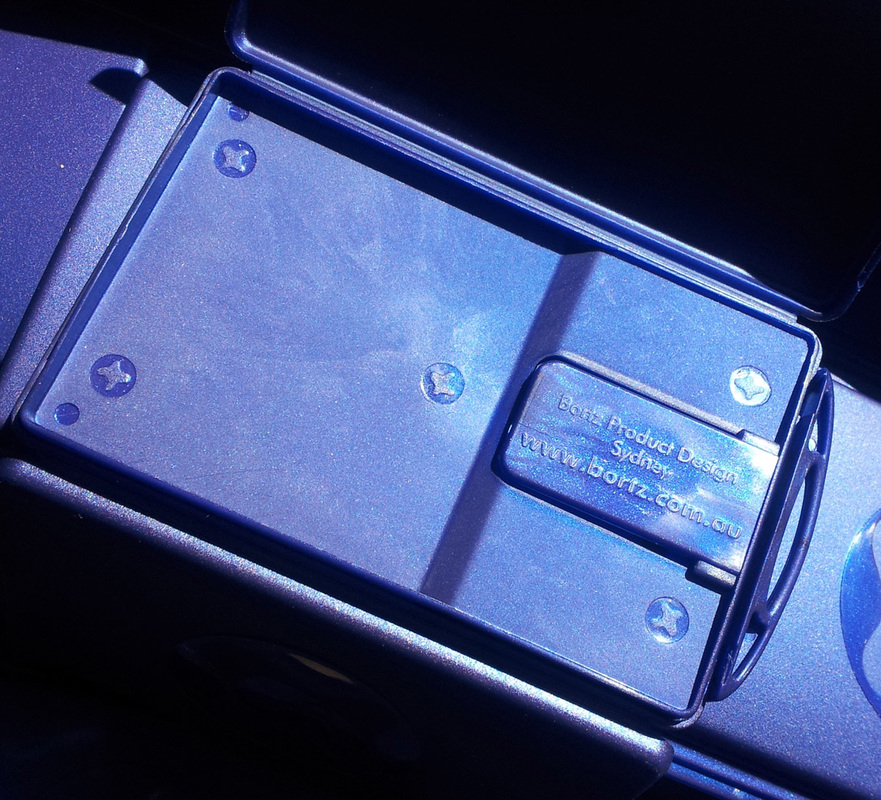

If you don’t already know me, you may be thinking “Slacker. Are you nuts? What kind of designer are you?”. My response is “an open minded one”. In the last year I have heard the term mindfulness a great deal. It seems to be the latest popular approach to life, but a little like 3D printing it has been around for years, only now becoming mainstream. I was first exposed to the idea of opening yourself and allowing solutions to come to you when I was studying design, over 30 years ago. With this approach we were encouraged to take our design brief and dissect it to its essence; to understand the real issue needing to be solved; brainstorm all solutions, not excluding any and feeding one’s mind with possibilities. We were then encouraged to take a break, perhaps go to the movies, let the ideas percolate and let the universe deliver the answer. Seems a ‘hokey’ idea, but it works. “Mindfulness” some may say. For me, giving my subconscious or ‘the universe’ time to do the heavy lifting, means taking a ride, and I am so fortunate that the bush is almost at the studio’s backdoor. Not a ride where I still ponder the answer, but one where all my conscious brain power is focused on keeping me upright, enjoying the surrounds and having fun. In essence, for me, it is a kind of meditation – an experience of being totally in the moment. Then, afterwards, with my mind clear, the answers seem to come to me - The ”Universe” delivering the answer. The poem “Clearing” by Martha Postlethwaite encapsulates this concept well. I believe the essence of this poem is not to try solve the whole puzzle by actively dwelling or thinking about the solution, but to free a clearing in one’s mind and wait for the answer to be delivered into one’s “cupped hands”. I am not sure that the Tax Office has yet adopted a mindful approach or would accept that my bicycle should be a tax deduction, but I would suggest that the next time you have a particular tricky challenge, that you adopt a mindful approach, take time out from trying doggedly to solve it, and rather take the ‘ride’ approach. The Bortz Double Hung Sash Window Breezeway LockWhen we build our new home and fitted stylish low profile aluminium sash windows we were troubled to find that we could only lock them in the closed position and if we wanted to leave them slightly open in a "beezeway" position, we had no security. After numerous family, friends and clients making the same complaint to me and then my in-laws building a new home where this problem again reared its head, I decided to solve this problem. Researching on the web, visiting hardware stores and approaching window suppliers confirmed that although there are many locks on the market for locking sash windows in a totally closed position and some that will lock the window in either a fully closed or slightly open, breezeway position, they were mostly for timber windows or aluminium windows, with wide sash frames. Modern extruded sash windows can have very low profile frames, with almost no vertical sash member exposed from the main frame and therefore locks cannot be mounted correctly or their locking pin cannot be inserted without interfering with either the window pane, guide mechanisms or seals. In addition to this, if they were able to be used, they would only lock one of the sashes allowing the second to move freely. The Bortz Window lock solves this by mounting to the top rail of the inner sash and locking into the vertical frame of the outer sash in an orientation perpendicular to the window pane. This locks the 2 sashes together such that they can be either locked in a slightly open breezeway position or a fully closed position. When unlocked it allows the 2 sashes to pass each other unhindered. This innovative patent pending solution has been prototyped and put through its paces over the past year. It was easy to install and has been simple to use. The results are good.

We are now looking for expressions of interest from manufacturers or distributors to take on this design. If you are interested in licencing or purchasing this solution, please contact us at sashlock@bortz.com.au or give us a call. Get a slice of your pie. So you have come up with a good idea and believe it is going to make you really rich. Well it may, but how? What is your plan?

The idea is always the easy part and from my point of view as a designer, creating the product is also an easy part in the equation. Some projects may pose technical challenges, however with research, design and development these can be overcome. Conceptualizing, designing, prototyping and manufacturing are all fairly quantifiable and mostly predictable and can be planned and budgeted for, but making back your money and more is a little trickier. So to get a little reality let’s do a quick checklist: Question 1: Are you doing this for fun or do you really want to make money from it? Do you just want to develop the product to fill a need you have, or to say you have produced your own product, or do you want it to generate an income stream? Question 2: Have you done your market research? Do you know if your idea really fills a need or gap in the market? Have you really checked to see if it has already been done? You have no idea how many meetings have been cut short, by me doing a really quick google web or image search and showing the prospective clients their idea has been done – sometimes a hundred different ways. Don’t just search for what you think it should be called, dream up synonyms, and even describe it. If you don’t find the idea here, dig deeper, do patent or intellectual property (IP) searches. If you haven’t found your idea yet, ask why - is it really a good idea, or maybe you just think so? See if others think there may be a market, and a word of caution here, most people cannot see or image different ways to solve problems and this may stifle a good idea by a lack of vision. Question 3: How are they going to make money from it? Obviously you want to make money, but how. Just having your product does not mean people will “beat a path to your doorway” to buy it. Like I said, having the idea, designing and manufacturing the product are all pretty easy and mostly the “cheap” part in this process. How do you intend to sell it? If you are not already an established business this can be really challenging. I would guess that most people would want to hold on to their product, have full control of it, in the belief that this is how they are going to make the most money. This path carries the highest risk, but could bring the greatest reward. Be aware, setting up distribution systems to handle the product from manufacture to your end customer requires infrastructure, marketing and advertising. Not only does it costs a lot, but requires specialist knowledge, a lot of energy, patience and nerves of steel. Do you have the balls? If you think that you do not need all of this as you are going to sell your product (in the singular) to retailer and they will take care of this for you – think again. Most retailers do not want to deal with stocking a single product line from a supplier unless it is a high value item with a good profit margin. The time and effort it requires is just not worth it. If you don’t have what it takes to sell your own product, all is not lost, there are other ways to reap the reward for your good idea. There are the options of selling your idea (your Intellectual Property), or licensing it to companies that may be aligned with your idea and have the distribution network and expertise to sell it. To do this you will either have to patent the idea or take out some form of intellectual property (IP) protection. For more information on IP visit (https://www.ipaustralia.gov.au/) IP Australia. This site has all the information you will need on your various protection options, as well as allow you to search to see if your idea has already been done, which is an essential part of your market research. Alternatively pay a visit to your friendly patent attorney and pay them to do this for you. IP only gives you ownership to your idea and negotiating the sale of your idea with a package that includes the IP is twofold – one, it protects you from being ripped off and secondly it give you something to sell. But as I have said before, the idea is the easy part, and to just sell a naked idea may not get the reward you are after. Too add value and command a greater return you should develop or refine your idea. To do this you should consider some serious industrial design input that at the very least produces some photo-realistic concept images or takes the design to some form of 3D prototype. The ultimate package to negotiate with would include, IP, and a well-designed working product, that has been prototyped, tooled, manufactured and a pilot run done. Industrial designers can help you with this, and it would assist in proving your concept and its possible market viability. This is back to the risk reward balance and dictated by how well you have done your market research, how deep your pockets are and how much stress you are prepared to live with. So my advice to entrepreneurs with great ideas is to be realistic. Do your homework and assess your particular situation. Rather than be too precious of your idea or too greedy, do what you do well, and work with a team that could make your idea return a bigger reward. Always remember, it is better to have a slice of the pie than to pay for the ingredients, but have no pie at all. This ultra compact, super light, extremely practical answer to carrying your essentials was inspired and conceived over 12 years ago after we were leaving an outing from the beach. We were bitching about our brick size wallets and decided there must be a better solution - especially for sport and the outdoors. The product had to be small, rugged and stylish. Carry 2 - 3 cards a few coins and some cash - "the 3 c's". Once one the market it became apparent that we should have called it the C4, as condoms became the next item that was fitted in. (But that is another story). Our solution was to mould it in plastic, making it durable, splash and sweat resistant while incorporating simple but elegant styling. It features a two compartment design, one for cards and the other with its integral cash clip to hold your hard earned cash, a recess for coins, condoms or other stuff. Its two covers clip closed securely and the lanyard / key-ring loop gives you carrying options. Using PP plastic meant that we could create an integral hinge, which has a life of over 100,000 of openings, requires no assembly or extra parts and is very small. It also means that the entire product is moulded in a single material which makes recycling it easy. Attention to detail was critical and the "Bortzie" logo was added into the traditional ejector pin marks making them more interesting and part of the design, rather than a blemish on the design. Our contact details were added to the note clip so that it would be predominantly displayed, with the aim of getting more traffic to our site and possible sales of the product. The final result is a wallet that I personally have used and abused for over 10 years. It has been around the world, on many mountain bike rides, snowboarding, hiking and just boring every day use. It was a fun personal project, which not only gave me a chance to design and manufacture my own product, but taught me a few lessons in marketing and distribution as well as. When Bill Findlay approached Bortz Product Design to assist in developing a cattle feeder that would be more durable, lighter, modular and able to be moulded, the result was a design from out of this world. The resulting solution, rotationally moulded in UV stabilised LLDPE, outlasts and out performs traditional metal feeders . They do not rust, last longer are modular and lighter - making them easy to transport and once in the paddock easy to move. As the plastic can flex when the cattle press up against the trough, it does not hurt the cattle or deform the feeder. This design has resulted in a product that free range cattle and Australian cattle producers are happy with. For more information about these uniquely designed Australian owned and manufactured cattle feeders visit Roswell Ag's website. |

AuthorGary Bortz, Director of Bortz Product Design Categories |